Similar Posts

Protected: Java Update Guide necessary for CellFusion Compatibility

ByJesseMThere is no excerpt because this is a protected post.

Protected: My Volume of Changes in Oracle Agile PLM

ByJesseMThere is no excerpt because this is a protected post.

Protected: Lead Design Engineer @ Ichor Systems – Dielectrics Division (Centura Systems)

ByJesseMThere is no excerpt because this is a protected post.

Protected: Quality Management System for ISO 9001 Certification

ByJesseMThere is no excerpt because this is a protected post.

Protected: PLM & Program Manager @ Applied Materials – Centris Sym3

ByJesseMThere is no excerpt because this is a protected post.

Conversation Starters

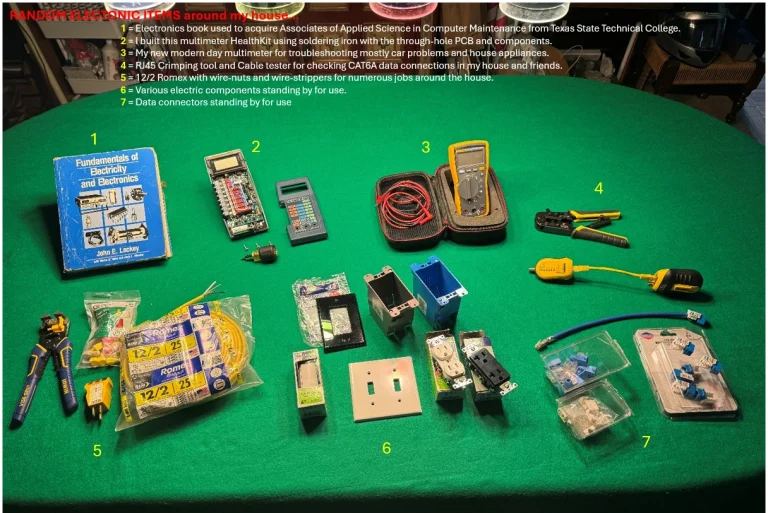

ByJesseMThis is simply a picture that shows my interest in electricity and electronics. The legend at the top describes things in more detail.